Packaging, one of the main application areas of plastics, has recently undergone drastic changes. On one hand, the growing spending power of the middle class has been pushing packaging towards the high end of being intelligent and personalized. On the other hand, as we enter the era of “new retail”, product delivery has been gaining popularity, leading to the expansion of the packaging market. Functionally speaking, innovations in packaging are geared towards extending the shelf lives of products, reducing food wastes, and improving product safety. At the same time, packaging is becoming a multi-purpose carrier integrating marketing, product management, and big data analysis. However, the industry is still being challenged by rising raw material prices and other costs, as well as pressure from environmental issues.

To swim with the tide is the key to survival. But how? Answers are to be found at CHINAPLAS 2018, the Asia's no. 1 plastics and rubber trade fair, replete with cutting edge solutions from around the world, featuring the latest materials, equipment and technology, providing a “high-speed train” for businesses to join the bandwagon.

Packaging "slimming" is in full gear Reducing resource consumption and packaging-waste at the source is not exactly a new idea, and "lightweighting" has been gathering momentum in recent years. Enterprises with leading technologies are already on the move, like Nestle. They have reduced the weight of their mineral water bottles by 30% - 45%, help saving the environment.

Ingeo-based Earthfirst UL, to be displayed by NATUREWORKS LLC at CHINAPLAS 2018, is an outstanding sealant with proven mechanic properties and performance. EarthFirst UL is ideal for food packaging applications like disposable pillow pouches, small coffee packets, gusseted stand-up pouches, frozen foods and multi-wall bags. EarthFirst UL forms superior seals at lower initial sealing temperatures. EarthFirst UL has great aroma barrier, grease-resistant attributes.

Taizhou Huangyan Fow Mould Co., Ltd. will showcase IML box mould /thin-wall mould at CHINAPLAS 2018. Fow Mould can be used to make various kinds of bucket mould, and of every size - from 50ml to 2L, in every shape - square container, round container, oval container, for every application - ice cream, cheese, chocolate, fast food and so on. The thin-wall mould can reduce packaging weight.

A bright future for biodegradable plastics Biodegradability is a rising star in packaging. On February 7, 2018, the General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of the PR China released a new version of the "Packings for Express Service" series of national standards and made it clear for the first time that courier packaging should make use of biodegradable plastics. According to statistics, the courier industry in China used about 14.7 billion plastic bags in 2016. It is an inevitable step to take to resolve the conflict between packaging and the environment and accelerate the pace to adopt green, biodegradable materials and technology.

PHA bio-based fully biodegradable polymers from Sogreen Technology Co., Ltd. can be decomposed by microorganisms within 3-6 months. The polymers can substitute 50% plastics. It can be used for the production of disposable products, such as mulch films, plastic bags, and foam lunch boxes.

Zhejiang Hisun Biomaterials Co., Ltd.’s REVODE Polylactide Resin is made from 100% renewable resources. REVODE is an environmentally-friendly material, produced with low carbon-emission methods. Products made of REVODE are 100% biodegradable. It is widely used in disposable tableware and packaging bags. Visitors can find out more about this resin at CHINAPLAS 2018.

What is the appeal of multifunctional packaging?

It has been derived that the amount of food wasted in Asia every year due to packaging problems is enough to feed more than a hundred million people. Common cause of such wastes is rotting or the growth of mould within shelf life. Is there a way to improve and use suitable materials to ensure or even extend shelf lives? The development of multifunctional materials with good barrier properties and are heat-resistant, UV-resistant, antimicrobial, permeable yet oxygen-blocking, can be an answer. Multi-layer flexible packaging films require specialty barrier extrusion lines. Films produced by Hosokawa Alpine Aktiengesellschaft - Film Extrusion Division prevent the infiltration of oxygen, nitrogen, carbon dioxide and water vapor. They also preserve the aromas and flavors of the finished product. It is recommended to use on 7-, 9- or 11- layer lines – the more layers the more options for users to engineer and tailor their film products while saving raw material costs.

The Hong Kong Polymer Science Ltd. will introduce CVI additive masterbatch and compounding solutions for food packaging and container applications to visitors. This exhibitor provides a full range of transparent compounds and additive masterbatches for PE, PP, and PA - solutions for the production of multilayer high barrier films, solvent-free lamination films, cast PE film, transparent containers for food and water, etc.

Don't manufacture harder but smarter

The structural shortage of labor has caused a surge in manufacturing costs, but the "Made in China 2025" strategy provides a solution - smart manufacturing.

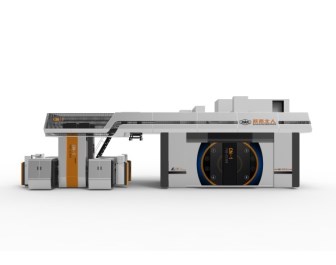

The digital intelligent printing factory FOE-CI350 satellite EB drying printing machine to be displayed by Shaanxi Beiren Printing Machinery Co., Ltd. provides real-time feedback and resource management according to data. The exhibit shortens delivery time by 20% to 25%, saves labor costs by 15% to 20%, saves capital costs by 20% to 30% and reduces material costs by 10% to 20%.

Han King Plastic Machinery Co., Ltd. will introduce a 3-layer FFS heavy duty bag coextrusion line which connects to an internal embossing device and a 4-color printing machine. It is suitable for producing bags used for packing resin materials, cereals, fodders, seeds and so on. It helps saving energy and takes only a short time to set up for mass production. The maximum output can be up to 350kg/hr. Its one-stop design - from blown film, surface treating, printing, embossing to final rewinding - helps reduce space and related costs effectively.

Guangzhou Jeepine Intelligent Compression Molding Machine Co., Ltd. will showcase a high speed 48 cavities cap compression molding machine. Capacity can reach 1,500 - 1,875 pcs/hr. With the addition of measuring pump, caps weight precision can be ensured. Output efficiency is 50% higher and energy consumption is 50% lower compared to injection molding machines.

A sneak peek at the concurrent events

A number of events targeted to the packaging industry will be organized during the trade fair to enhance technology exchange. At the “3rd?Industry 4.0 Conference”, practical cases of 4.0 factories will be discussed, and ways to optimize automated manufacturing and improve the efficiency of product assembly and workflow will be explained. There are more than 80 technical seminars that you cannot miss! As well as the “Bottles Recycle Program: Re-create Together” co-organized by CHINAPLAS, INCOM TOMRA Recycling Technology (Beijing) Co., Ltd. and a special sponsor, Hangzhou Wahaha Group Co., Ltd., a leading beverage producer in China.

CHINAPLAS 2018 will take place on April 24 – 27, 2018 in National Exhibition & Convention Centre (NECC), Hongqiao, Shanghai, PR China, with “Smart Manufacturing”, “Innovative Materials”, and “Green Solutions” being the show focuses. It is expected that 4,000 well-known international suppliers will be showcasing new machinery, materials and technical solutions in a 340,000sqm exhibition area, including BASF, Dow, DuPont, Kuraray, Natureworks, Mitsui Chemicals, LG Chem, Exxon Mobil, Shaanxi Beiren, Arburg, KAUTEX MASCHINENBAU, BRüCKNER MASCHINENBAU, Diyi Machinery, Akei, Taizhou Huangyan Daelong, TAKEBISHI, TOTANI, Han King, SUNCENTRE, Changsengda Machinery, Siemens, Autodesk, etc.

It is expecting more than 180,000 professional visitors from 150 countries and regions will come for business, procurement and technology exchange. Past visitors including well-known brands and enterprises like Wahaha, Master Kong, Uni, Nongfu Spring, Mondelēz International, Kraft Heinz, Danone, Coca-Cola, L'Oréal, Unilever, P&G, Blue Moon, Huangshan Novel, CH Packing and Bemis etc.

To pre-register now, please visit www.ChinaplasOnline.com/prereg. For more information about CHINAPLAS 2018, please visit www.ChinaplasOnline.com.

+86-576-81126888

+86-576-81126888

export@lefnmould.com

export@lefnmould.com

Address:

NO.111,Mingxing Road,Xinqian,

Huangyan(318020),Taizhou,Zhejiang,China